i.) Rolling Barrier

• Safety Rolling Barrier protects the passengers and drivers from a fatal traffic accident.

• The Safety Roller Barrier needs to be installed at sites where vehicles are exposed to frequent accidents.

• The Safety Rolling Barrier minimize fatal damage by converting shock energy into rotational energy when the car crashed the rollers laterally.

Features

- Reduction of shock energy by roller’s spinning.

- Help a vehicle turn back to the road by roller’s spinning.

- Excellent shock absorbing by EVA Roller

- easy maintenance (Assembling construction)

- Barrier’s height can be easily adjusted for passenger car and lorry

- Highly cost effective

How Safety Roller Works?

- Roller absorbs collision shock (shock energy -> rotational energy)

- Front rail absorbs 2nd shock

- Back rail absorbs 3rd shock

- Metal pipe inserted in to strengthen post

Product Material

- Shock absorbing Roller : A highly polymerized (E.V.A-Ethylene Vinyl Acetate)

- Post : KSD3566(STRUCTURAL GALVANIZED STEEL PIPE)

- Safety Rail : KSD3503(STRCTURAL GALVANIZED ROLLED STEEL

Advantage

- Shock absorbing roller system by it’s spinning when the car crashed the roller

- Reduction of shock energy by roller’s spinning

- Help a vehicle turn back to the road by roller’s spinning

- Excellent shock absorbing by EVA Roller

- Easy maintenance (Assembling construction)

- Barrier’s height can be easily adjusted for passenger car and lorry

- LED GUIDE LAMP(Powered by solar energy)

- Highly cost effective shock absorbing safety roller

ii.) Water Fountain

We create beauty, tranquility, and awe inspiring effects with water. Our fountains and water features enhance the natural beauty of their environment. From traditional fountains, to water falls, to interactive fountains with music, lights, and multi-media, our fountain designs create atmospheres for work, study, health, inspiration and play.

Our planning staff starts with an understanding of your vision and goals. Then our award-winning professionals interpret, design, engineer, construct, and maintain your water feature. On Fountain , we DESIGN , BUILD AND PROVIDE SERVICES.

FOUNTAIN DESIGN

Design & Drawings will include:

- Water Feature Plan and Section Views

- Complete Suction and Discharge Piping Diagrams

- Water Feature Equipment Layout and Bill of Materials

- Water Feature Electrical Schematic and Layout Drawing

FOUNTAIN INSTALLATIONS

We build the fountain either its regular or floating . We make the installation as per the client’s requirement.

FOUNTAIN SERVICE

Totally unique , RAY COMMUNICATION has been created for the design, construction and vault fabrication of new fountains and water features, as well as service and maintenance for those existing. Outdoors or indoors … in a mall, at a hospital or other institution, as a municipality landmark, on a corporate campus, for a welcome to a residential area, or to create drama to a retail environment, you can rely on the unmatched experience that only RAY COMMUNICATION can provide.

FOUNTAIN EQUIPMENT SUPPLY

A water feature’s performance is a direct result of the equipment that is installed. It is imperative to employ top-quality fountain components that are ideal for the desired effect. All of our electrical components, including our custom-built control panels, are designed to meet UL’s stringent standards. Our goal is to provide you with the optimal water feature equipment package to suit your application. We can provide you with an ideal, complete package.

FLOATING FOUNTAINS

We can supply and install a variety of lake aeration systems and floating fountains to improve the water quality and aesthetics of your pond or lake.

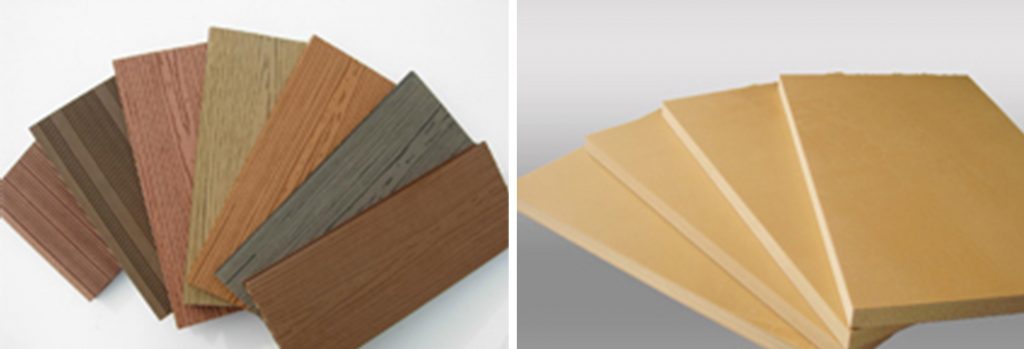

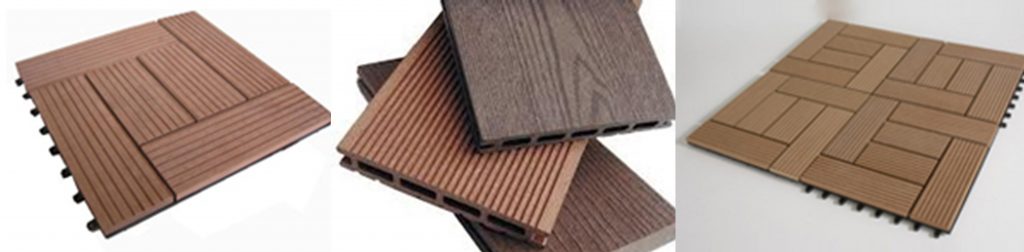

iii.) Wood-plastic composite

Wood Plastic Composites (WPCs) are produced by thoroughly mixing ground wood particles and heated thermoplastic resin. WPCs do not corrode and are highly resistant to rot, decay, and Marine Borer attack, though they do absorb water into the wood fibers embedded within the material. They have good workability and can be shaped using conventional woodworking tools. WPCs are often considered a sustainable material because they can be made using recycled plastics and the waste products of the wood industry. In recent years, people in the flooring industry starts referring to WPC as a type of floor that has a basic structure of top vinyl veneer plus a rigid extruded core (the core can be made without any wood fiber).

WPC board uses

WPC board for Modular Kitchen

Kitchen is the place where water proof furniture is crucial. The wood plastic composite is an ideal option of ply. It can be used to provide specific look of the particular space with attractive view. So it is so beneficial to use WPC board for modular kitchen.

WPC Board for Furniture

Traditional trend of furniture making is replacing with WPC board for furniture due to several limitation of wood that is compensated with WPC boards. Wood is tends to shrink and swelled in moisture and humidity. More over it can’t resist water application. There is possibility of fungal existence in wood.

WPC Board for Wall Paneling

WPC is made 100% recyclable material. It is the best and cost effective alternative of wood or cement. It is splinter free. It is an ideal material for various applications due to its good resistance to weather. It contains good surface hardness. It is paint friendly. SO it is an excellent choice to make wall paneling.

WPC Board for Windows

We are well known manufacturer and supplier of WPC board for windows. It is believed as ideal choice for making windows due to its good resistant property. Windows are supposed to face the rain water, sunlight and other weather conditions. WPC boards are ideally resist and been unaffected with water and moisture.

WPC Board for Construction

WPC boards contain excellent moisture resistance. It can be made with innumerable applications of colors, designs and patterns. We are tagged as chief manufacturer and supplier of best quality WPC board for construction with varied configurations.

WPC Board for Wall Cladding

We hold most modern manufacturing unit to offer best quality WPC boards. It is made with celuka structural foaming process system. It contains ideal quality to fabricate wall cladding. It is easy for cutting and sawing. It also offers high impact resistance. It is convenient with lamination and gluing. It offers good nail and screw holding capacity. It can be easily cladded for wall making. Wall with WPC board offers good water resistance and moisture resistance. It is fad resistant and can be used for making durable partition or wall. WPC board for wall cladding is novel criteria to make eye catching arrangement by wall cladding.

WPC Board for Ceiling Solution

We are well recognized manufacturer and supplier of WPC board made from reyclble wood and thermoplastic materials. It is made with wood dust, fibre and polypropylene, polyethylene and PVC and other thermoplastic materials. It can be ideally used for forceiling due to its 100% flawlessness. We precisely choose the raw material for the fabrication.

WPC sandwich boards

WPC boards show good set of performance but monolithic composite sheets are relatively heavy (most often heavier than pure plastics) which limits their use to applications where low weight is not essential. WPC in a sandwich-structured composite form allow for combination of the benefits of traditional wood polymer composites with the lightness of a sandwich panel technology.